Archive

It’s Hard To Make Things Easy…

I have often been asked how I came into the field of consulting, and how that career path forked and diverged into successful projects in several manufacturing and service industry companies. It began when I went to work with James Abbott. I was an early hire for his training organization and continued to work with him as we transitioned into a training and consulting group.

James had a vision. He saw the training and professional development need that every company has; and he decided to address that need with in-depth training seminars on a wide variety of subjects.

I had an academic background in physics and math and had a strong work background in Information Technology. I always have an appetite to master new material and I told James that I would come up to speed in any training material he wanted to offer. This turned out to be a perfect fit to my personality and skill set!

The Secret To Great Training

We worked hard to develop and organize the training materials in proper order from the basic to the advanced. Our course design approach was to always establish a context for new ideas. We often reminded each other that counting comes before arithmetic, arithmetic before algebra, and algebra before calculus.

This conceptual approach allowed us to effectively present a large amount of material in a compressed period of time. When community colleges began teaching computer skills classes – their instructors took two days of our material as a template for a semester long course.

What Students Said

James has a saying, “It is easy to make things hard and complex. It is hard to make things easy and simple!” This principle was obvious to me after every seminar that I taught. The student reviews typically fell into two categories.

I was disappointed with reviews like this: “The material was very advanced. I learned a lot. The instructor was an expert in the material and presented it very well” . Instead, I wanted to see reviews like this: “The class was easy. The time went by fast. I think I may have already known a lot of the material beforehand.”

With the same subject, similar audiences reported different experiences. I could always account for this particular difference by how I organized the material. I could tell that proper order was one important key to participants “getting” the material. (Arithmetic Before Algebra!)

The Principle Applied to Process Improvement

Any business, service industry or manufacturing process can improve if we learn something new and integrate it into the context of our existing knowledge. New process tools, knowledge and metrics are the principal drivers of improvement. Every process will degrade when we start to forget, and we let known manageable factors return to the dark unknown.

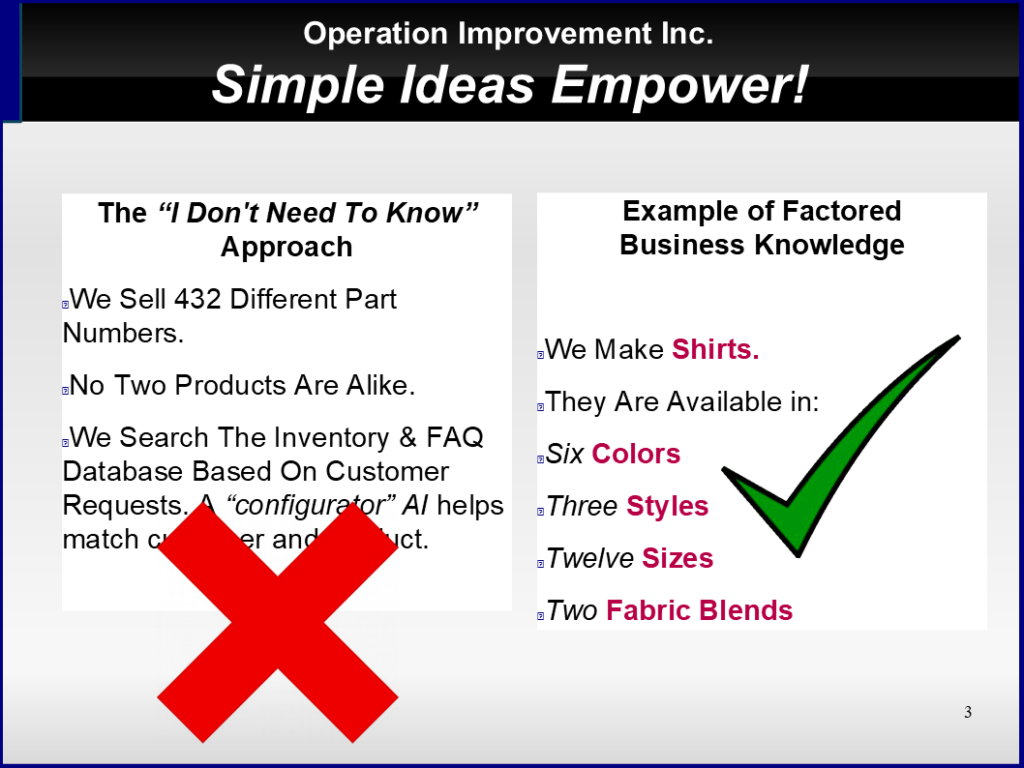

Learning and sustainment begins by conceptually building that contextual foundation. What do we know? When we start a consulting project, we often encounter this: “It’s all the same. A call is a call. An order is an order. A cast iron part is a part. It’s pretty obvious.”

When pressed for details on how things work and how tools are used, this posture then flips and becomes: “Our processes are so complex. You wouldn’t understand. No two calls in the call center are the same. No two customer manufacturing orders are the same. No two system failures are the same.”

We call this retrenching position: the “no two snowflakes are alike” response, and we then explain what we are looking for:

(1) A difference in degree that is a difference in kind: For example, 2- or 3-minute calls in the support center versus 30-minute calls. “Short calls” versus “extended calls”, or “quick feature training calls” versus “software installation and configuration calls”. These might be approached as two different processes.

(2) In manufacturing, we might want to think about similar products made from copper or aluminum versus wood. These might be considered as two processes if the end result differs only in material. “Soft Metal” versus “Woodworking”.

Is This Too Simple?

When teaching these first process concepts to beginners, they first object that this seems too simple. It is simple, once this “factor analysis” has been done!

Is This Too Hard?

Charles Hobbs was an important thought leader in the field of Time Management, and he once told a parable of a woman who found purpose when she was encouraged to start by examining what was in her own back yard. She found a rock – a steppingstone rock near her back door and she began to ask herself, “What kind of rock is this? What else can it be used for? What is its mineral content?” After a time, she became quite knowledgeable about minerals and when she felt that she had reached a goal she asked for advice again. Her mentor, replied: “What was under the rock?”

When even experienced engineers grasp the implications of recursively drilling down into processes to learn more, to “look under the rock”, they often experience a moment where it all seems never-ending and too hard.

Simple is not the same as easy. Creating a culture of learning in yourself and in an organization is hard work. However, a culture of learning results in better decisions, better products and services lower costs and hopefully – a virtuous circle of continuous improvement.

Reports Are Not The Same As Data!

At the start of a new operations process development or improvement effort, I typically want to see two things firsthand.

It is important to have a personal view of the work presently being done, as well as the methods and the tools or resources available at the place of effort. It is also vital to get an early look at the process metrics and performance outcome data that the workers and their management think is actionable. These first steps allow us to start with a clearer picture of the objective (the deliverable) and begin to develop a vision and implementation plan for a better way.

What I frequently get in response to my requests is one or more reports instead of data. Where once there might have been actual data, its source and method of capture is undefined and cannot be audited. What began as observations systematically compared to a standard has been digested into predetermined narratives with implicit and often wrong conclusions.

Data means measurements, with the method of measurement totally transparent and always open to constructive critique, caveat and refinement.

As an example, telephony systems have not always left audit trials for call center operations.(And many today do not meet the standard of measurement above.) In the systems that do have call detail databases, much time and effort is spent trying and failing to reconstruct the “state of the business” at some past date and time.

I approached this problem on an older system by taking and saving periodic real time snapshots of the PBX system state. (Calls in queues, current wait times, etc.) These frequent “state of the business” measurements gave us actionable data and helped us to monitor performance as we made changes and introduced new methods and tools to call center agents.

The entire chain of logic (observation, data grouping, statistical summation) and graphical reporting was presented in a form that not only provided actionable information, but also communicated the answer to this most important question, “How Do We Know?”

Of course, measurement in the service sector has the same issues of measurement variability as precision measurement in manufacturing. The solutions to this challenge are similar, but that is another topic.

“If we don’t have a clear picture, then we don’t act!” ** – Organizing Product and Process Knowledge

For centuries, people took for granted that the sun and heavens moved around the earth. Against that night sky was the surprising, independent and often retrograde movements of the planets. How does one make sense of that? How does one grasp, in principle, that contrary movement?

Of course you know the answer, as does every child who grew up with a ceiling-mounted mobile of our solar system. We now think of the (1) sun as stationary. We (2) imagine circular motion around the sun, and then refine that new conceptual model by adding more knowledge. We learn that those planetary orbits are (3) elliptical. Then, we discover that (4) not all planets orbit in the same horizontal plane. (Mercury and “sometimes-a-planet” Pluto are tipped a bit.)

As we learn more, the mental picture does indeed become clearer. If our job is to launch a spacecraft to another planet, this clear picture is vital. We need as complete an inventory as possible of what is known about the solar system and its moving parts. We don’t stop at four metrics. Organized Knowledge is power.

Businesses can often make quantum leaps in their ability to deliver value, if someone takes an independent and objective look at how workers and managers think about their jobs. If product and process learning has slowed or stopped, you may need a fresh approach that “puts the sun at the center” of your thinking.

Take a look at the difference a clear picture makes:

- A tech support team dreaded every phone call. A fresh look at their processes led to change, and they were confident in their job after a week!

- A metal machining operator reduced job setup time from four hours to 15 minutes when a fresh look at the process reduced the setup of hundreds of parts to just a dozen or so basic configurations.

- The wrong mental picture caused a service desk to deliver worse performance while their metrics showed improvement! A fresh look at their metrics turned this around immediately.

It is hard to make things easy.

Your high school English teacher probably warned you about too long sentences. Many people will not get a clear picture unless you break ideas down into manageable sentences with nouns and verbs. Product and process knowledge should be organized in absorb-able chunks for similar reasons.

We often say that properly organized process and product knowledge is a mechanism to learn, share, teach and improve. It documents dependencies between ends and means – what are the prerequisites for successful results.

We call this approach to improvement: factoring. We have been coaching, teaching classes, writing books and running on-site improvement projects based on these methods for over two decades. If you see opportunities to apply this in your operation, we are here to help.

—-

** “If we don’t have a clear mental picture, then we don’t act!” This is one of the most memorable gems from Dr Charles R. Hobbs, but there is more to unpack than the surface meaning.

Re-Engineering a Contact Center’s Support Desk Processes, Tools and Metrics

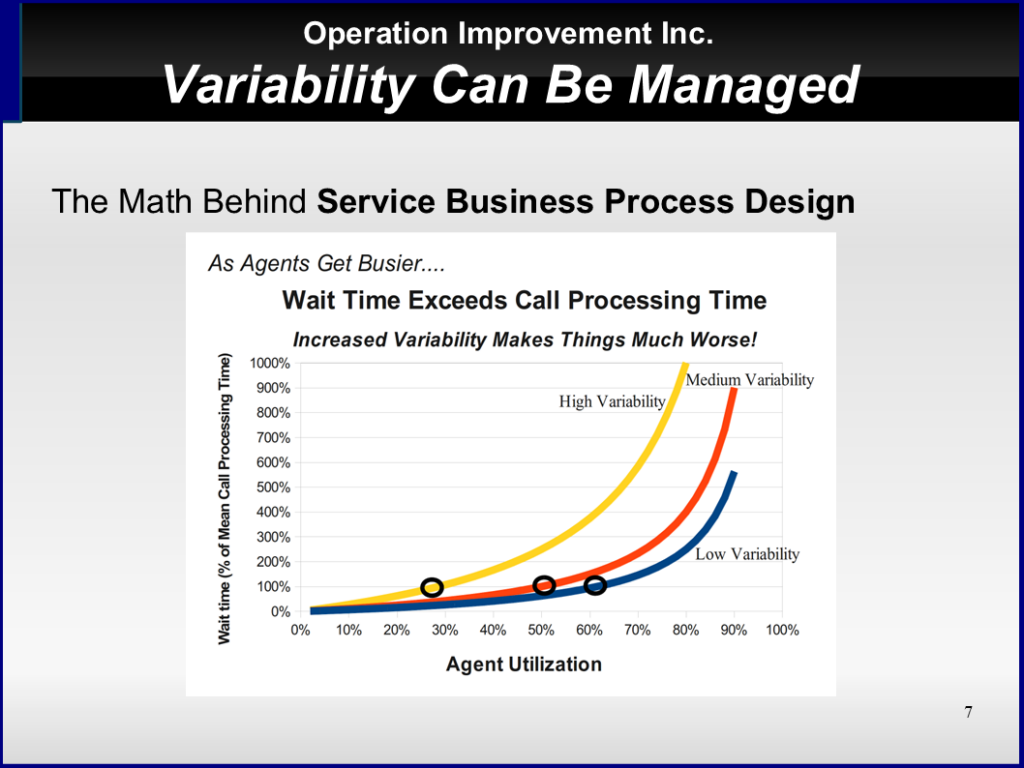

Actionable metrics are conclusions that rest atop a careful pyramid of reasoning that has first-hand observation at its foundation. This is true, even in the realm of precision measurement where we quantify things too small, too big, too fast, too slow or too abstract the see with unaided senses.

Attribute measurement, where we drop events into categories, is very common in contact center metrics. When, where and how many cases by type is often where categorical analysis begins, but if the measurement foundation if flawed, then the conclusions will be weak and uncertain.

True Story!

One client had well over 100 agents providing Technology support for the company’s workers in all 50 states. Their old Remedy ticketing system always had them start a new call and a fresh ticket with a “Category, Type & Item” ticket type. An audit of calls showed that most of these tags were so vague as to be useless or simply wrong.

Here is what we did to re-structure the process.

First, agents were trained to understand that the classification was provisional. It could be reclassified once all evidence was in.

Second, we looked at the anatomy of their Technology infrastructure, and reconstructed the category, type, item choices accordingly. (We have successfully used this anatomical approach to clarify the scope of support in other organizations.)

Now, the most important part!

We added three fields with behind the scene changes to the ticketing software, and modified the agent process like this:

When each call came in, we documented “Symptoms”. The field names and work flows reflected this early first step – and pick lists of previously reported symptoms suggested a provisional category, type and item.

Every support call starts with at least one symptomatic behavior in tech, but analysis cannot stop there. A given symptom may have a benign cause, a serious cause, or may be a complex interaction of two or more causes. So the next modification to the process was this:

We trained our agents in the basic anatomy of the systems that they support so that they could attempt to code a “Diagnosis” the cause of the problem. Too often, support centers are happy to simply make a symptom disappear instead of identifying causes and dependencies. Our process approach emphasizing cause identification allowed the support organization to take preventative action for all users that would be impacted by that same cause, but who had not yet experienced trouble!

Finally, the process of closing a ticket now included “Outcome” (a case resolution discussion) and a final classification of category, type and item.

Obviously, there were nuances. We created simple dependency diagrams that allowed agents to quickly grasp technology anatomy. There were TIER I and TIER II division of labor and escalation issues, and sub-tickets and master tickets were used to collate up cases by cause. Re-organization of TIER I into teams that specialized in specific and related systems had a positive impact on training time and call outcomes. Of course, call routing had to be analyzed and re-engineered to reflect all process changes.

However, the result was a new and improved paradigm in that organization for support center “best practices”, and since this project, we have seen some of these ideas imported into other organizations and into later generation ticketing and contact center software.